Key word: Alnico Magnet

Material: Alnico2, Alnico4,Alnico5,Alnico8 etc

Application: Electric guitar pickup,Magnetic coupling,Magnetic Workholding,Speedometer,Educational etc

Guitar Pickup Magnet: In brief, when the strings begin to oscillate, these oscillations affect the field in the vicinity of the pickup magnet, it induces a change in the flux of the magnetic field. Thus, there is a week current, the electrical signal is transmitted to the amplifier by wire. Finally, it comes into being the sound. The magnets are at the heart of the pickup there are two main types of magnetic materials used: 1, Alnico-Aluminum Nickel Cobalt Magnet First developed in the early 1940’s, alnico magnets are associated with mellow tone, a smooth response and a moderate output. This guitar pickup is suited for Blues, Jazz and Pop. Alnico magnet is divided into Alnico 2(Alnico II), Alnico 3(Alnico III), Alnico 5(Alnico V) and Alnico 8 (Alnico VIII). The common guitar’s magnet in market is Alnico 2(Alnico II) and Alnico 5(Alnico V). The magnetic intensity of alnico 2 is lower than alnico 5, so it can create more mellow and warm sound. The famous user of alnico 2 is SLASH. Alnico 5 can create more powerful and smooth sound. Alnico 5 is used for NUNO-N4, DIMEBAG WASHBURN, NECK-SH1-59, SH4-JB, SH2-Jazz, EMG85 and TONE ZONE. 2, Ceramic or Ferrite – Strontium Ferrite It was developed as a low-cost and manufactured since 1954. The magnetic intensity is stronger than alnico magnet and has much better corrosion resistance than rare earth. The guitar pickups with ceramic magnets usually have a brighter sound. This guitar pickup is suited for Hard Rock and Metal. Ceramic is used for JOE, VAI and VAN HALEN. Standard size: D5X14 D5X18 D5X15 D5X20 D5X16 D3.2X3.2 D5X16.5 D4.75X19 D5X17 F63X12.7X3 D5X17.5 F63X12.7X3.2

|

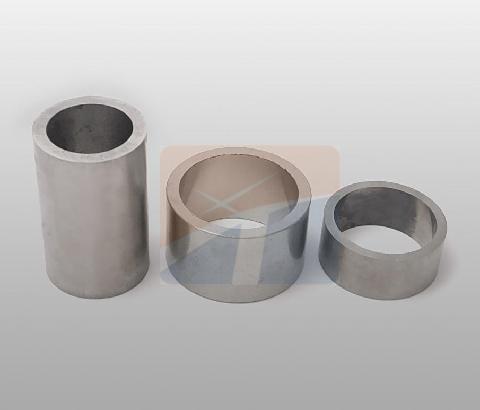

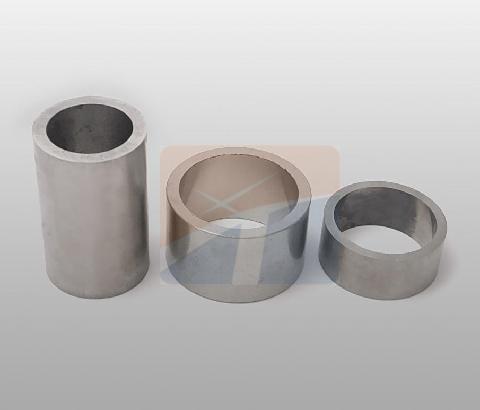

Magnetic coupling Magnet: A magnetic coupling is a coupling that transfers torque from one shaft, but using a magnetic field rather than a physical mechanical connection. Magnetic shaft couplings are most often used for liquid pumps and propeller systems, since a static, physical barrier can be placed between the two shafts to separate the fluid from the motor operating in air. Magnetic shaft couplings preclude the use of shaft seals, which eventually wear out and fail from the sliding of two surfaces against each another. Magnetic couplings are also used for ease of maintenance on systems that typically require precision alignment, when physical shaft couplings are used, since they allow a greater off axis error between the motor and driven shaft. |

Speedometer Magnet: A speedometer or a speed meter is a gauge that measures and displays the instantaneous speed of a vehicle. When the car or motorcycle is in motion, a speedometer gear assembly turns a speedometer cable, which then turns the speedometer mechanism itself. A small permanent magnet affixed to the speedometer cable interacts with a small aluminum cup (called a speedcup) attached to the shaft of the pointer on the analogue speedometer instrument. As the magnet rotates near the cup, the changing magnetic field produces eddy currents in the cup, which themselves produce another magnetic field. The effect is that the magnet exerts a torque on the cup, “dragging” it, and thus the speedometer pointer, in the direction of its rotation with no mechanical connection between them. The pointer shaft is held toward zero by a fine torsion spring. The torque on the cup increases with the speed of rotation of the magnet. Thus an increase in the speed of the car will twist the cup and speedometer pointer against the spring. The cup and pointer will turn until the torque of the eddy currents on the cup is balanced by the opposing torque of the spring, and then stop. Given the torque on the cup is proportional to the car’s speed, and the spring’s deflection is proportional to the torque, the angle of the pointer is also proportional to the speed, so that equally spaced markers on the dial can be used for gaps in speed. At a given speed the pointer will remain motionless and pointing to the appropriate number on the speedometer’s dial. The return spring is calibrated such that a given revolution speed of the cable corresponds to a specific speed indication on the speedometer. This calibration must take into account several factors, including ratios of the tailshaft gears that drive the flexible cable, the final drive ratio in the differential, and the diameter of the driven tires. Universal size: Alnico2 or 5, 23*d13.5*3mm without injection molding 23*d6*(3.5-4)mm with 3,4 or 6 molding holes 23*d6*3.47mm |

| No.222 Chaohu Road. Xinbei district, Changzhou, China. | |

| Eric Wang | |

| +86 519-8518 9192 | |

| +86 519-8518 9199 | |

| eric@xt-magnet.com | |